Heirloom Cultivars

Produced by Banko Taratu Washing Station

Gedeb, Yirgacheffe, Ethiopia

Process - Extended Washed

October 2022 - January 2023 Harvest

Tasting Notes - vibrant orange jam, white floral tea, silky & soft

Another aged-harvest african coffee for you to enjoy

As Ethiopia’s coffee harvest is finishing up before being exported and sent on cargo ships around the world, we wanted to sample a lot of old harvest crop. About this time is when we believe a lot of Ethiopian coffees, and even other African coffees, have opened up and are tasting their best. While we wait for this new crop to arrive over the coming month/months (depending on region), we are excited to release an incredible coffee that showcases what the late-2022/early-2023 harvest year in Ethiopia had to offer!

This coffee comes from the Banko Taratu Site in Gedeb’s Gedio zone. This zone holds one of the highest coffee growing elevations in Ethiopia, up to a shocking 2,300 meters (7,546 feet) above sea level! The coffee is grown on over 300 family-owned (very small) farms, more associated as “home gardens” than high volume coffee production farms that are much more common in other coffee producing parts of the world outside of Africa (hello, colonialism). Though this is slowly changing with the sudden rise of single-producer farms selling to incredibly curious and surely risk-taking importers/roasters.

extended-washed fermentation processing

Once the coffee cherries are ripe, they are hand picked and sent to the nearest washing station where they are sold and sent off for further processing. Once the coffee cherries are depulped (removing the bean from the fruit) by a machine, the beans are steeped in tanks with fresh spring water for 24-48 hours to remove any fruit mucilage off of them. This is a bit longer than most coffees, hence the “extended” washed fermentation process. Mucilage is removed off of the beans with this process because acids are created through this immersed fermentation process which drops the pH of the water to create acidic conditions in the tank. The acids eat away at the sticky mucilage layer from the fruit that is still stuck on the coffee beans. The beans are then removed from the acidic water tank and then they are shade dried for a few days until a moisture content of 30% is reached. The beans are then sundried on raised beds for two weeks until a moisture content of 11% is reached. Coffee above 12% moisture can start to grow mold and lead to taste and hygiene issues. This is highly unwanted and best avoided in our industry (though some roasters want to experiment a with higher moisture content while shipping the beans via plane instead of cargo ship and roasting them within weeks of harvest). Coffee below around 9% is often said to contain less aroma, flavor clarity, and freshness because of how the beans roast inefficiently due to less heat transfer through moisture. This allows for heat to not reach the center of the bean during the roast, leading to underdeveloped flavors, or roasty flavors if the roaster chose to develop the inside, they’d need to burn the outside more. It should be said that some roasters with specific air roasting machines and great quality-controlled storage systems see this as less of an issue compared to other roasters.

our roasting approach

This cup profile is another great representation of a high quality, grade 01 washed Yirgacheffe. We roasted this coffee to have a floral vibrancy and a jammy texture. When we tested roasting this coffee with a more developed roast profile, it lead to intense florals. This flavor profile has been all too common with us for our past 2 Yirgacheffe releases, so we wanted to see if we could take this coffee in a different direction. We roasted hotter, faster, and lighter to make a cup profile that opens up for more citric components, and delicate florals that represent other floral flavors other than straight purple/white florals and purple/white candy. This is a great test to see what our roasting style is capable of, and we’re very happy with the outcome!

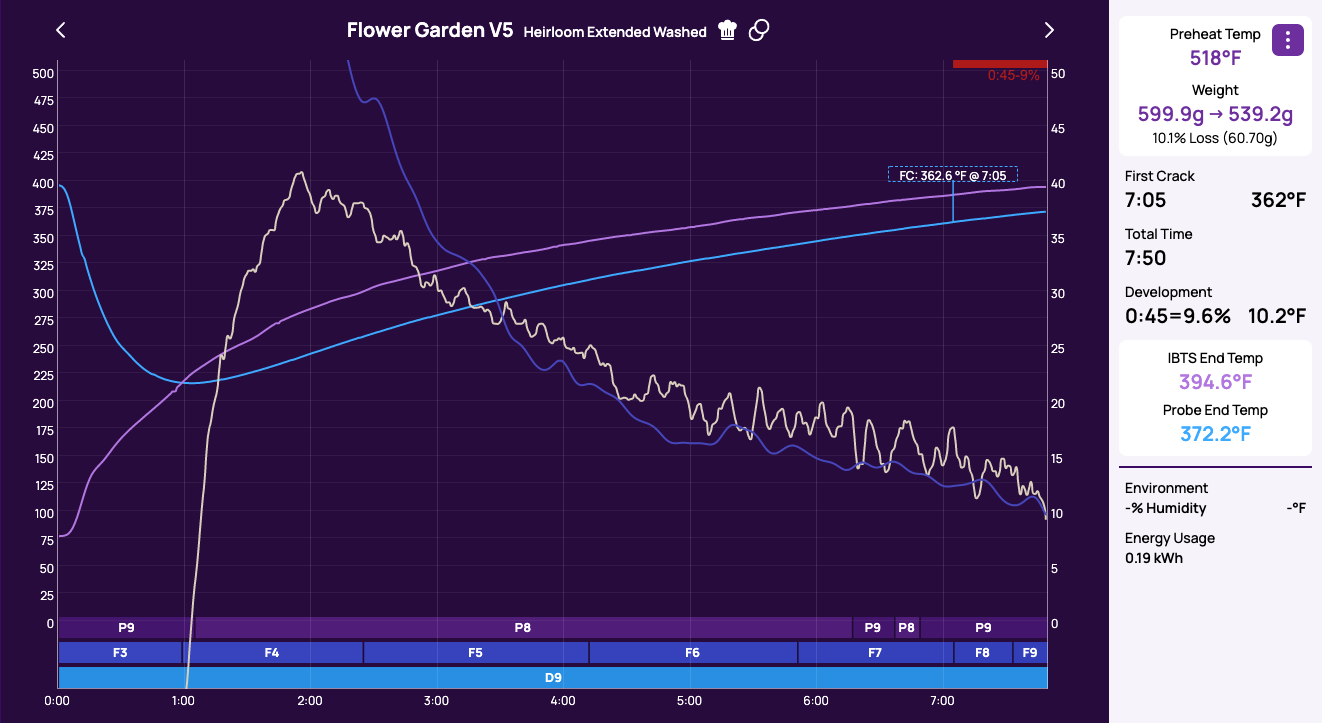

The Final Roast Profile

V2 roast was slightly under developed. We loved this roast, but wanted to avoid the sweet honey intensity from under development that was clouding some of the coffees citric and floral flavors. Notice how the weight loss percentage is 10.3%? We wanted to roast with slightly more development to boost that number. In our final profile, that percentage was 10.6%.

V3 was our attempt at roasting with more development. This roast showed us that this is what our coffee tasted like with roasty flavors. This is beyond the upper limit of where our roast profile should be. We now have examples of under and over roasted profiles, which creates our desired “sweet spot” range! The weight loss is 11.2% - significantly higher now. We want to be below that range, ideally.

V5 was our attempt at roasting faster with MORE heat via an 18 degree higher charge temperature. Attempting to keep most variables the same, this roast started first crack nearly 1 minute before our final profile. I was hoping more heat would cook the bean more efficiently to avoid those under roasted flavors. I was wrong, this was under roasted and tasted like sweet honey still.